ebco GmbH is a medium-sized company from Albbruck in southern Germany.

We develop and produce PU moulded foam parts – from the raw material to the assembled component.

More than 100 employees manufacture our high-quality products in 5 halls on an area of 7,000 m².

We work to achieve utmost customer satisfaction.

Our actions are characterised by ensuring excellent quality and meeting deadlines.

We are constantly looking for innovative solutions and enjoy accepting challenges. We focus on achieving agreed targets, both externally and internally.

We keep an open and solution-orientated communication.

We aspire to be the benchmark in our field.

We consider optimisation of work mechanisms and production processes as a continuous task. The consistent usage of

increase our effectiveness and efficiency.

We also utilise the knowledge of external consultants to improve our processes for the manufacture of high-quality products.

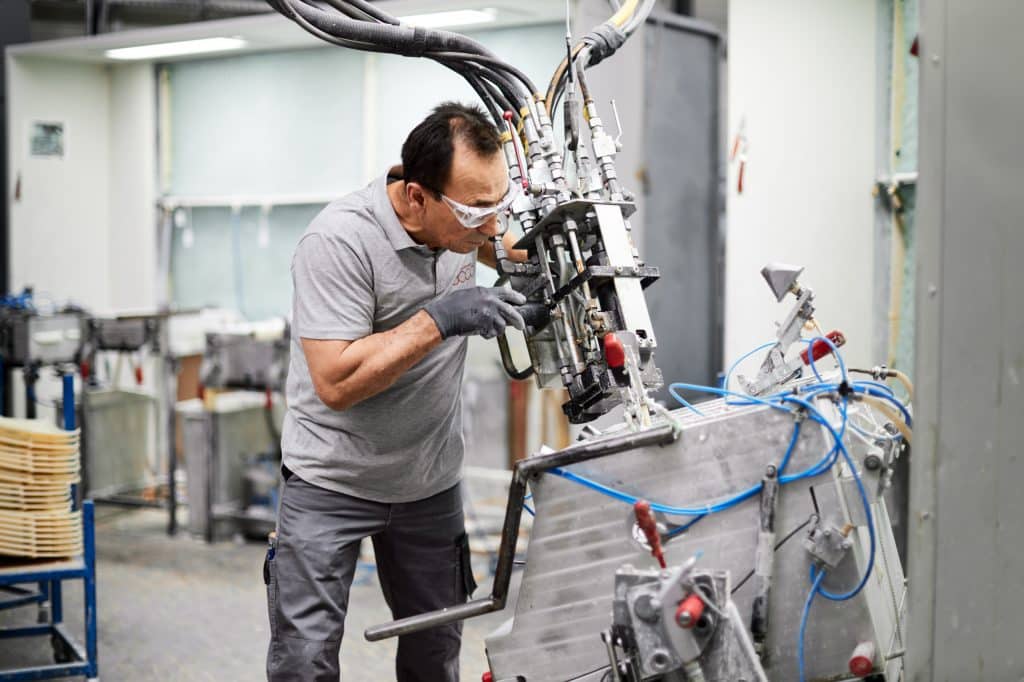

Young, motivated trainees, experienced employees with many years of service, highly qualified specialists and a highly respected workforce.

We are proud of our employees..

Sie bilden unser Rückgrat.

We pay attention to ongoing training and ensure a good and safe working environment.

Creating and securing jobs is part of our corporate philosophy.

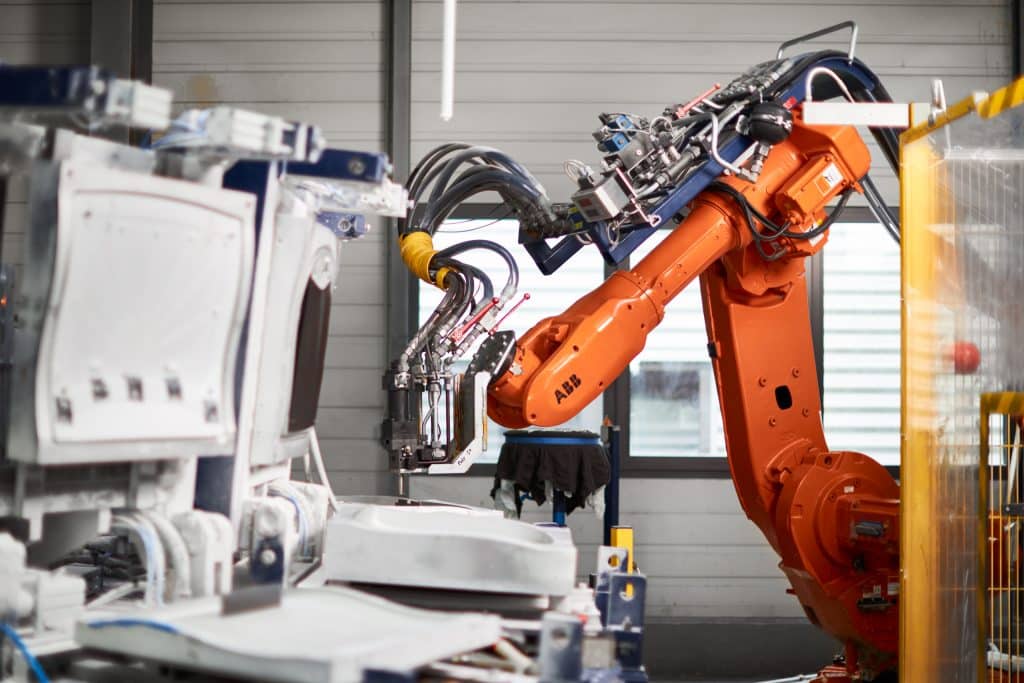

Our production lines are "state of the art" and include a variety of moulded foam equipment, thermoforming systems, further processing lines, milling robots, labelling stations and more. We use them to manufacture products such as:

The possible applications are diverse

Fulfilling national and international environmental requirements is been taken granted for us.

"Circular Economy" is already a reality in our production

We also protect our environment by

We have been fulfilling the standards of the Quality-Management Systems since 1997, currently in accordance with DIN EN 9100.

Since 2009 we have complied with the voluntary Environmental-Audit 14001.

Our most important certificates/approvals: